By Siti Zulaikha Shawaludin

Fakhrul Shawaludin and his partner, Jesse Lucas based in Los Angeles, California, USA have created CR8 (create) to provide a 3D printing solution for the prosthesis market, catering specifically to the needy children, which is an overlooked market.

This is a story of the invention using a 3D printing technology which has dramatically improved the life of a little girl.

The 3D-printable prosthetics are changing the face of medicine, as virtually anyone and anywhere can print this device. The 3D printed hand is an alternative to conventional prosthetic hand. Majority of prosthetics today are limited in design and functions.

The 3D printed hand has more flexibility, range, and lower cost. They are especially helpful for children who do not normally have the option of traditional prosthetic device due to cost, time, or due to the uniqueness of the limb difference.

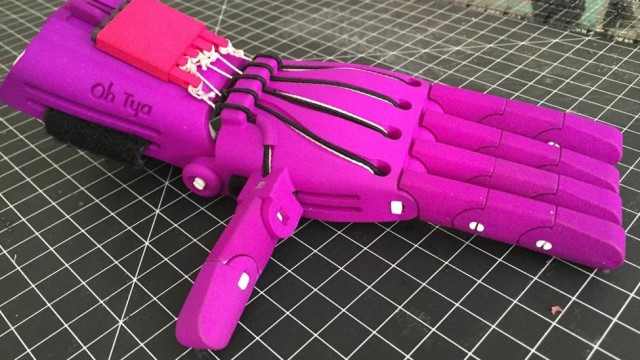

This takes a helping hand to an entirely different level. Although made of cheap plastic, the hands are sophisticated and individually tailored to the point where kids can use them for daily activities such as grabbing a water bottle or a ball.

Fakhrul Shawaludin, the founder of CR8 was inspired by the idea when he met his wifes best friend, Shikin Shuriani and her amazing daughter, Tya Orked. Tya was born with a deficiency called Amniotic Band Syndrome, which caused a number of different birth anomalies like deformed limbs or digits, cleft lip and palate, clubfeet.

œTya was born with a birth anomaly and during one of our many conversations we talked about her growth and interests. Being an exuberant and enthusiastic mother, Shikin taught Tya to be fearless and embrace life to the fullest. As a 6 years’ old child, she had many interests and one of her interests is music, specifically the piano.

“That conversation triggered the thought of creating an affordable, safe, customisable and durable set of prosthetics that will grow with her and fit her needs, said Fakhrul.

There is nothing more inspirational than seeing parents go all out trying to improve the quality of life of their children and see them succeed. It was a great moment for an amateur designer like Fakhrul to see Tyas reaction to her new hand the first time she put it on.

œIt was a pleasure and unforgettable experience to be able to make the prosthetic hand for her and seeing her with it, the feeling is priceless, added Fakhrul.

Children like Tya, born with missing a part of limbs and to custom prosthetic replacement would often require thousands of dollars. However, CR8 has changed her life by using 3D printing technology and created this affordable and useful device.

What inspired Fakhrul to take on this journey was mainly the advancement of the technology. Fakhrul added, œThe potential of technology is one of the key elements that inspires me. Technology has such potential to create change, impacting change and be the change. It also depends on the end user of technology, thats why I feel that providing change by utilising technology excites me as it has so many possibilities.”

University of Malaya Medical Centre, Kuala Lumpur conducted a five-day study in 2001 and reported a total of 13% of diabetic patients admitted to the orthopaedic wards for diabetic foot problem. Amputations, either major or minor, are the common surgical procedures performed for this group of patients.

The main purpose of amputation is to remove the diseased tissue and maintain the patients best chance for ambulatory rehabilitation. In Kuala Lumpur Hospital, 20% of diabetic cases admitted to the orthopaedic wards had major amputation while 31.7% had minor amputation. Moreover, diabetic foot complication accounts for almost 700 amputations annually in Singapore.

Furthermore, over 64,000 land mines and ERW (Explosive Remnants of War) casualties have been recorded in Cambodia since 1979 and with over 25,000 amputees with this, Cambodia has the highest ratio per capita in the world. Having 3D prosthetic limbs, at a low-cost solution would help lower the cost for the patients.

The goal of CR8 is to provide a œhelping hand to the disabled community not just in Malaysia but also regionally within the ASEAN region and scaling worldwide. They also tend to give special outlook towards children because children outgrow their prosthetics too fast, which is why the current market does not address their needs.

Because the hand is 3D printed, each one can be modelled and designed specifically to its wearer. The scanner will scan the body parts to which the hand is to be fitted and uses that as a basis for the print, scaling the length of the prosthetic as required. The scanning process can be completed within a few minutes. Each hand takes about 20 hours to print and another two or three hours to assemble.

The cost varies, as the designs are dependent on the individual in terms of fulfilling their needs. Designs can be customised, to fit the individuals and dependent on which materials they choose to use. The overall weight is light as they are made from ABS plastic; a common thermoplastic polymer, generally used by LEGO Company.

Although the wearer will not have the sensations or feel what the prosthetics are touching the mechanism will help the wearer to get a grip on something. For example, a prosthetic hand used the contraction of muscles to close the fingers by flexing the wrist, which will pull the cables that connect the wrist to the fingers. Move the wrist again and the hand opens.

These devices have certain weight limit in which it can hold and the force it can withstand. It cannot hold more than a few pounds of weight and the grip strength is not that strong on most of the designs and cannot be used for playing on monkey bars, doing handstands, or anything else that may lead to harm, the device may fails or breaks.

Additionally, the fingers do not move individually “ they have a simple basic grasping function which will only allow them to move together.

The 3D printing technology is a dynamic and evolving technology and the main challenge CR8 currently faces is funding; CR8 wants to advance the technology while keeping the costs low.

œWe would like to make this as affordable as possible especially to lower-middle income family, Fakhrul said.

In addition, œThe fact that we are located in the USA is also a big challenge, when we want to serve to the needs of people back home in Malaysia and Southeast Asia.

The founder of CR8 further noted their hopes for future is to be able to have more collaboration locally in Malaysia “ œto have more involvement with universities as we would also like to have this 3D printing labs set up in Malaysia.”

“We want to encourage the millennials and Generation Z about the potential and possibilities that lie in the STEM (Science, Technology, Engineering, and Maths) field as well as to inspire them to be more innovative. As the world is changing, the needs are also changing, and we would like to be in the forefront of change, Fakhrul said.***

Visit here!